Analysis

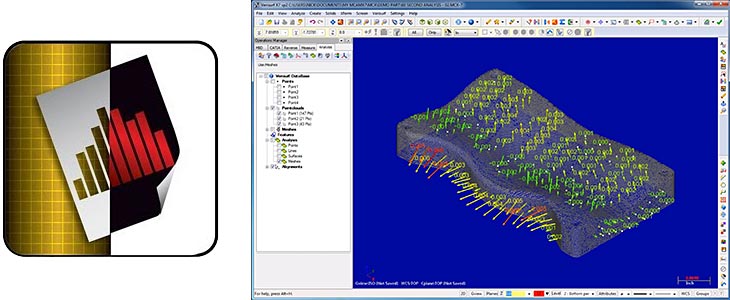

Our industry-leading software provides the Common Platform for product data management by interfacing with all types of CAD models and measuring devices in real-time, enabling manufacturers to seamlessly and fully conduct the functions of part design and machining. Verisurf software combined with your measuring device provides a simple 3D Gage for quickly and accurately measuring parts and comparing them to the nominal CAD model.

Analyze Points to Any CAD Model

Whether the source is CATIA, SolidWorks, UG, Pro-E, or any other CAD system, Verisurf Analysis quickly and efficiently analyzes part tolerance by comparing measured points to nominal features in a CAD model.

Verisurf Analysis features a powerful, flexible, and fully-controllable 6-DOF best-fit to find the optimal tolerance condition for a set of measurements. Best-fitting uses a rapid, iterative least-squares solution to align measurements to the model, producing minimum analysis deviations without regard to a datum alignment (reference). Use this versatile alignment tool to orient data sets – and the measurement device – to the CAD model even in the absence of datum features. Best-fitting can also reduce scrap by revealing the intolerance condition of parts that would otherwise be rejected based on an incorrect part alignment.

Customizable “best-fit” capabilities innovatively determine the optimal fit between the data and the model. For reporting Verisurf Analysis generates Excel-based text and HTML-based color reports including color deviation mapping for clear, practical analysis.

RECENT NEWS

Did you know? IIA’s Irvine, CA Lab has one of the Largest Area Laser Scanner CMMs in the U.S.