3D Scanning

3D scanning has become an increasingly effective and popular way of capturing surface geometry due to strides made in accuracy and speed in both 3D scanners as well as point cloud data processing. The resultant measurement data can be highly dense allowing it to be processed in creative and useful ways. Of particular use is the ability to measure with great detail features and characteristics that previously were either extrapolated or simply excluded from conventionally obtained and sparse data.

3D scanning has become an increasingly effective and popular way of capturing surface geometry due to strides made in accuracy and speed in both 3D scanners as well as point cloud data processing. The resultant measurement data can be highly dense allowing it to be processed in creative and useful ways. Of particular use is the ability to measure with great detail features and characteristics that previously were either extrapolated or simply excluded from conventionally obtained and sparse data.

3D scanning can be especially beneficial for:

- Airfoil shapes such as turbine and impeller blades

- Organic geometry such as the human form, dental impressions, and archaeological artifacts

- Contoured exteriors and interiors of automobiles

- Any complex, non-prismatic geometry, with or without variable curvature

Q-PLUS Labs has an extremely wide range of 3D scanning capabilities including triangulating laser, conoscopic laser, white light, blue light, chromatic confocal, time-of-flight laser, phase-based, photogrammetry, and various contact technologies. Also see our CT Scanning page for more 3D scanning options.

3D Laser Scanning

With this type of 3D scanning system, a laser is projected onto the surface of an object and a camera captures the reflection. The laser can be in the form of a single point, a line, or an entire field of view. When the reflection is captured, each point is triangulated, measured, and recorded, resulting in a 3D rendering of the shape and surface measurements of the object.

|

|

|---|

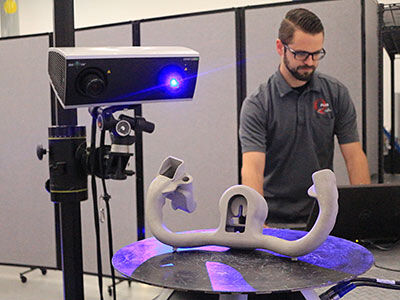

White & Blue Light Scanning

White light scanners, also referred to as structured light scanners, use halogen or LED lights to project a fringe pattern onto an object. Such scanners may also use other colors of the light spectrum, such as blue or red light, though the effect or improvement in results is small. The distortion of the pixels created by the object’s surface and the resulting light pattern can be measured and used to reconstruct a 3D image.

|

|

|---|

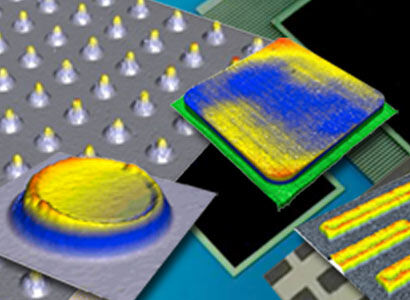

Nano Scanning

3D Scanning at the sub-micron level is accomplished with sensors such as confocal white light or white light interferometry. This type of scanning can be used to measure or digitize very small geometry and can also acquire surface roughness data.

|

|

|---|

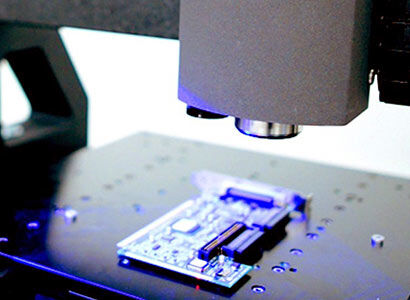

CMM Scanning, Continuous Contact, Touch Probe & Hard Probe

Coordinate Measuring Machines (CMMs) are mechanical systems that use a measuring transducer technology to convert probe and physical measurements of an object’s surface into electrical signals that are then analyzed by specialized metrology software. There are many different types of CMMs. The most basic systems use hard probes and XYZ read-outs, while the most complex employ fully automated continuous contact probing.

|

|

|---|

Optical CMM Scanning

Some applications call for a portable solution, for example taking measurements on a shop floor or in the field. In these cases an Optical CMM can be used to gather measurement data for areas that are difficult to reach. The hand-held device transmits data wirelessly and allows the operator to move both the part and the scanner during the measuring process. Using stereoptics to scan an object, the Optical CMM uses 2-3 cameras to track either passive retroreflective or active targets through space. This process allows objects to be rebuilt in 3D via the device’s reflectors.

|

|

|---|

Articulated Arm Scanning

An articulating arm is a type of CMM that uses rotary encoders on multiple rotation axes instead of linear scales to determine the position of the probe. These manual systems are not automated, but they are portable and can reach around or into objects in a way that cannot be accomplished with a conventional CMM to perform 3D inspections, tool certifications, CAD comparison, dimensional anlaysis, reverse engineering, and more.

|

|

|---|

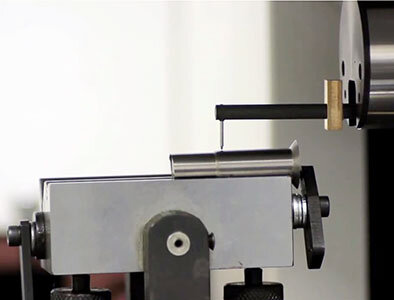

Digital Contour Tracing

Form and contour tracers are purpose-specific devices that use extremely accurate, continuous contact sensors and styli to obtain small-part geometry. These devices are especially useful for scanning objects that include threaded, cylindrical, or rounded features.

|

|

|---|

Range Scanning

Range Scanning is a type of laser scanning using a time-of-flight laser rangefinder based on LiDAR technology to measure the distance between the laser and the object’s surface. The laser rangefinder sends a pulse of light to the object and measures the amount of time it takes for the reflection to return in order to calculate the distance of each point on the surface.

Point measurements are taken by aiming the device at the object and using a series of mirrors to redirect the light from the laser to different areas on the object. Although the process may seem cumbersome, typical time-of-flight 3D laser scanners can collect between 10,000 and 100,000 points per second, which is much faster though less accurate than contact sensors.

|

|

|---|

RECENT NEWS

Did you know? IIA’s Irvine, CA Lab has one of the Largest Area Laser Scanner CMMs in the U.S.