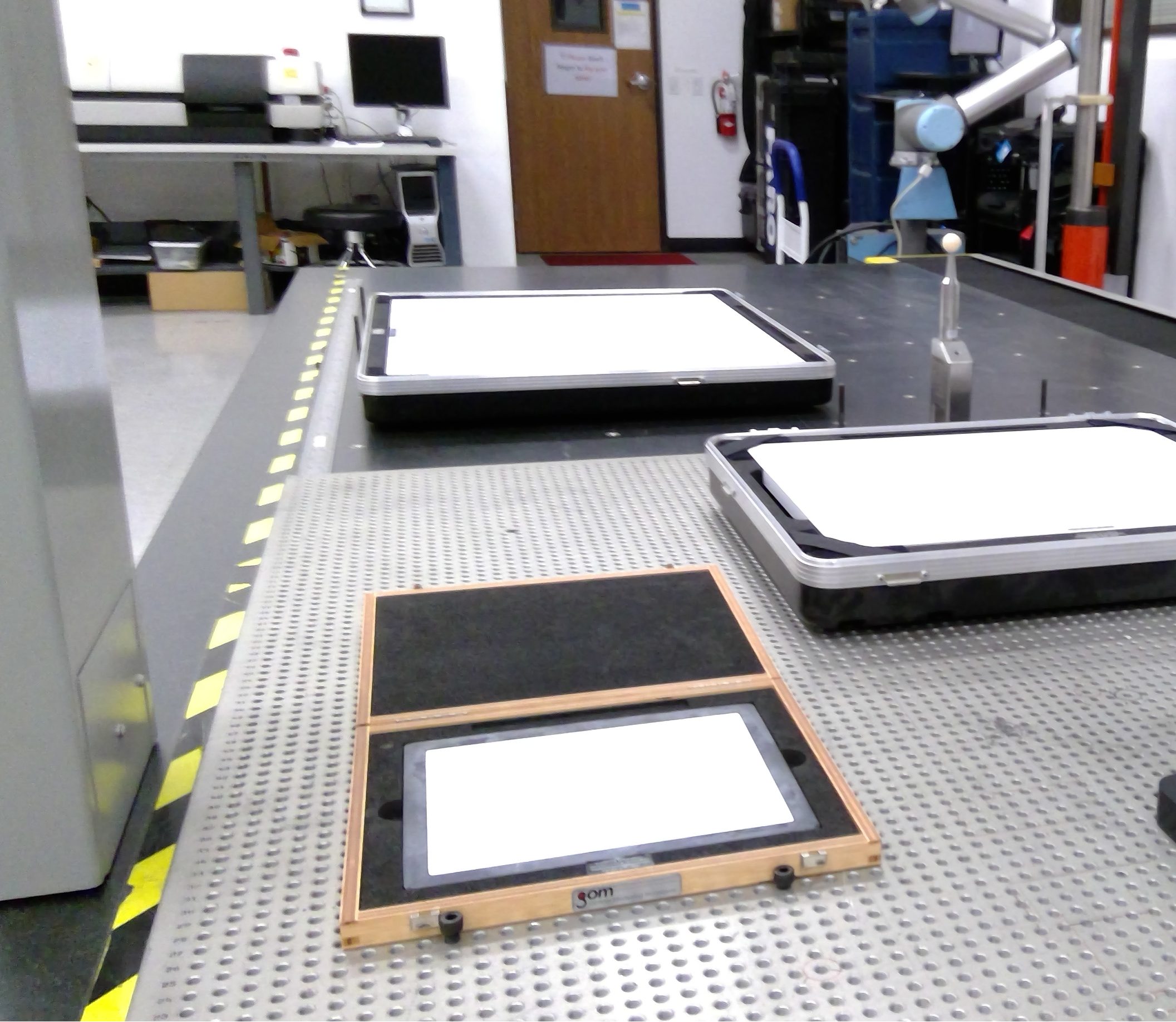

Brown & Sharpe BIG Hex CMM measures items up to 6’ x 12’

As a premier provider of advanced dimensional metrology services and solutions, Industrial Inspection & Analysis’s (IIA’s) Irvine, California-based lab, previously known as Q-PLUS Labs, proudly houses one of the most expansive area laser scanner Coordinate Measuring Machines (CMM) in the United States. The Brown & Sharpe BIG Hex CMM, equipped with a Hexagon HP-C-VE vision sensor, represents IIA’s commitment to providing customers with even more meticulous and comprehensive dimensional metrology services.

The BIG Hex CMM measures large, intricate parts with unparalleled precision. With the capability to measure parts up to 12 feet in length and 6 feet in width, and the capacity to capture millions of data points per second, this machine empowers us to deliver intricately detailed and accurate measurements — even for the most intricate components.

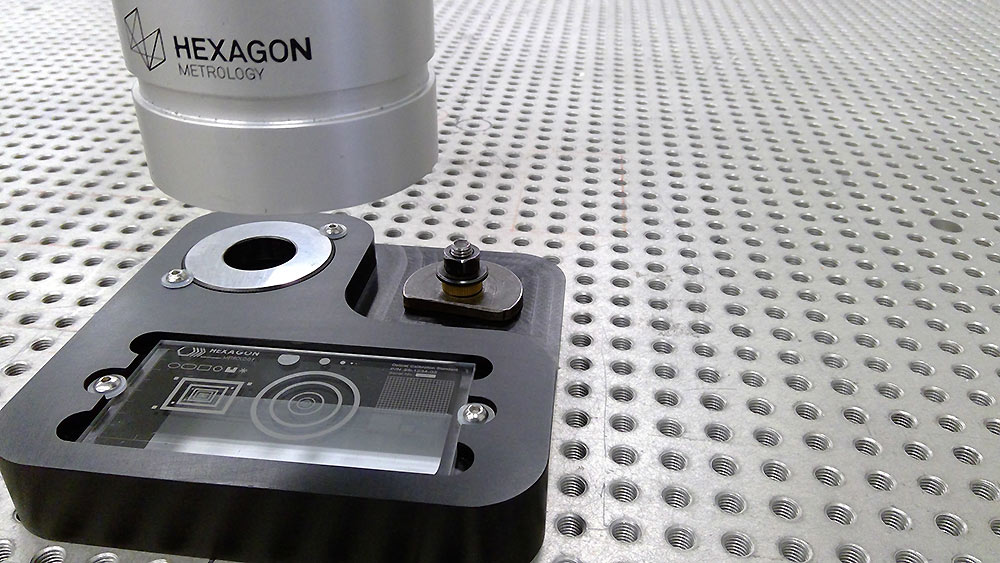

At the heart of this advanced system is the Hexagon HP-C-VE vision sensor—a high-resolution camera capable of measuring features that may be challenging or even impossible to assess with a laser scanner. Additionally, the sensor serves a crucial role in inspecting parts for any potential defects, enriching the suite of services we offer.

The inclusion of the BIG Hex CMM within our inventory of dimensional metrology equipment strengthens IIA’s position as one of the most exceptionally equipped dimensional metrology labs in the United States.

Advantages of the Hexagon Global Image CMM

The BIG Hex CMM extends several key benefits to customers:

- High Accuracy: The precision offered by the BIG Hex CMM is essential for customers seeking to ensure that their parts conform to stringent tolerances.

- Large Measurement Volume: With the capacity to measure sizeable parts, this CMM is ideal for inspecting large and complex components, such as automotive body panels and aerospace parts.

- Rapid Measurement Speed: The machine’s swift scanning capability helps in reducing inspection time and associated costs for customers.

- Non-Contact Measurement: The non-contact method used by the BIG Hex CMM, utilizing a laser scanner, minimizes the risk of part damage during measurement.

- Versatility: Its adaptability enables measurement of a wide array of parts—simple or intricate—making it a valuable asset for diverse manufacturing sectors.

Applications of the BIG Hex CMM

The versatile capabilities of the BIG Hex CMM render it indispensable across various applications:

- Automotive Manufacturing: Measurement of automotive body panels, engine blocks, and diverse automotive components.

- Aerospace Manufacturing: Inspection of aircraft wings, fuselage sections, and other aerospace components.

- Medical Device Manufacturing: Assessment of medical implants, surgical instruments, and related medical devices.

- Electronics Manufacturing: Measurement of circuit boards, electronic components, and other devices in the electronics industry.

- General Manufacturing: Versatile measurement applications across different industries, ranging from simple to complex parts.

Enhanced Functionality of the HP-C Vision Sensor

The HP-C Vision Sensor, integrated with the BIG Hex CMM, offers a range of practical benefits:

- Multifaceted Measurement Access: Utilizing multi-capture technology, the HP-C swiftly collects multiple measurement features, enabling efficient data capture for detailed analysis of individual features.

- Extended Measurement Field: The HP-C, in tandem with PC-DMIS software, efficiently captures and measures features beyond the field of view, significantly improving throughput for larger and diverse components.

- Accuracy Maintenance: Illuminating the work area, the HP-C ensures comprehensive data capture, featuring a higher resolution zoom to attain precise measurement results.

- Selectable Viewfields and Pixel Sizes: Operators can select various fields of view to measure more or larger features or opt for smaller measurement areas to achieve higher measurement accuracy.

- Camera and Illumination System: Equipped with a 3-megapixel camera and LED illumination, the HP-C delivers precise results, even in challenging conditions.

- Automated Sensor Exchange: Utilizing Hexagon’s kinematic joint interface, the HP-C enables automatic sensor exchange, supporting the use of multiple sensors for the same part on a single machine.

- Harmonized System: The HP-C was specifically developed for Hexagon CMMs and PC-DMIS software, ensuring compatibility and optimized system performance.

The integration of the HP-C Vision Sensor enhances the functionality and precision of the BIG Hex CMM, making it an even more versatile and robust tool for dimensional metrology across various industrial applications.

Adaptability Across Diverse Industries

The BIG Hex CMM offers an array of benefits, including high precision, large measurement capabilities, swift measurement functions, non-contact measurement, and broad applicability across various industries. IIA is dedicated to delivering top-notch dimensional metrology services, and the versatility of the BIG Hex CMM underscores this commitment.

For more information about the BIG Hex CMM or any of our extensive dimensional metrology services, please feel free to contact us today.

Leave A Comment

You must be logged in to post a comment.