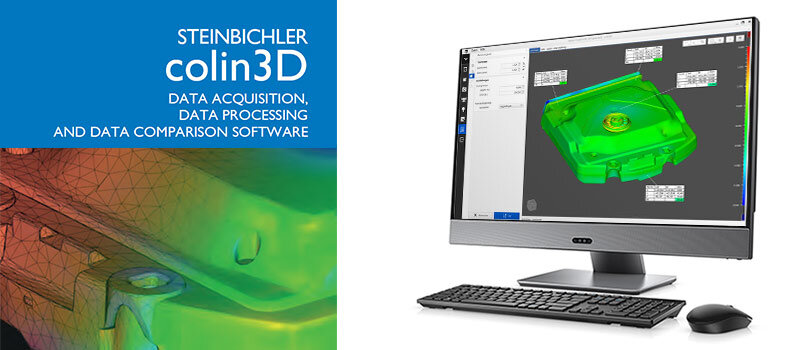

colin3D

Zeiss Industrial Metrology specializes in high accuracy measurement systems, including coordinate measuring machines (CMMs), computed tomography measurement machines (non-medical), optical measuring equipment, metrology software, and measurement sensor systems. Industrial measuring technology from Carl Zeiss ensures maximum standards of quality wherever high precision is a must.

The colin3D software for data acquisition, data processing, and simple data comparison is a high-performance companion for the COMET, Photogrammetry and T-SCAN sensor systems.

Innovative Functions

The new colin3D software platform is designed to ideally complement the COMET, COMET Photogrammetry, and T-SCAN sensor systems. The program independently identifies the ideal strategies for merging individual images (matching) and guides the user to an ideal result using a completely redesigned, project-oriented user interface. Thanks to the new CAD integration, the user receives continual feedback about the component surface areas that still need to be captured.

Maximum Performance

Based on years of programming experience with 64-bit operating systems and the corresponding hardware such as graphics cards and multi-processor systems, the new colin3D algorithms achieve maximum performance and data quality.

Optimum User Support

To quickly and efficiently position the T-SCAN system, the measurement field and scanner can be optionally displayed in colin3D, making it easier to determine the ideal tracker position. Measuring programs for applications using the rotary tables COMETrotary and COMETdual rotary can be easily created and executed. All individual measurements in a measurement sequence are subjected to quality checks and automatically repeated if necessary.

Data Analysis Functions

For quality assurance applications, the scan data can be compared on the surface of a CAD model using a simple best fit alignment. colin3D contains a simple false-color portrayal with a color gradient and fixed values. To more precisely analyze deviations, users can place the flyers on the surface individually. Reports for documenting the measurement results can be easily and quickly generated and managed.

Maximum User Friendliness

Thanks to the extremely user-friendly, reduced user interface, little training is required and the software is easy to work with. Adapted to the workflow, the standardized menu structure is logically and incrementally built and only contains the setting options that are of relevance to the application.

Highlights

- Integration of the COMET, COMET Photogrammetry and T-SCAN sensor systems

- Rapid triangle mesh generation

- Surface comparison with report function

- Intuitive mesh processing

- Partial filling, generation of bridges and simple filling

- Mesh smoothing/sharpening

- Mesh structure optimization (regularization)

- Different selection methods

- Documentation of the calibration process

- Service functions for monitoring system accuracy