Home > Services > Dimensional Inspection > Additional Inspection Specialties

Additional Inspection Specialties

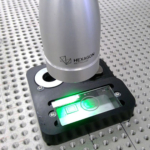

Ultra-High Accuracy Length, Thickness and I.D./O.D. Measurement

- 1 micro-inch resolution

- Temperature compensation

- Variable pressure or non-contact

- Gage calibration

In line with our philosophy of thoroughness and exactitude, we can measure outside and inside diameters and lengths with extreme accuracy, repeatability, and speed, using a variety of contact and non-contact instruments with resolutions down to one-millionth of an inch!

Thickness Measuring Capabilities

- Complex castings

- Forging webs and die closure

- Plastic and glass bottles

- Formed or drawn sheet metal

- Pipes and tubes

Thicknesses of all types of materials can be nondestructively measured with an accuracy down to 0.0001 inches and a thickness of up to approximately 20 inches using ultrasonic distance measurement (high-frequency sound waves) and Hall-effect (perturbations in a magnetic field) technologies. The applications are innumerable, the process is fast, and the cost savings are great because sectioning for access to the measurement of interest is not required.

Validation

We can assist you in validating your own measurement processes either by performing the same measurements in our laboratory or by comparison of alternate methods and instruments. Further, Q-PLUS Labs can assist in the systematic assessment of the factors causing measurement variation.

Measurement Studies

Measurement studies are performed where uncertainty exists in determining the ideal combination of applied metrology technology and resources, particularly for long-term arrangements. This is essentially where we take the seemingly impossible measurement job and make it possible—then we prove it and, if desired, implement it into your production measurement process.

Potting & Sectioning Capabilities

Potting and sectioning is useful for accurate measurement when no type of contact or non-contact sensor will properly detect geometry for parts such as rubber bearing seals.

Blue, Scribe & Layout

Some of our customers require that castings and forgings be inspected using the traditional blue and scribe method so one can “see” how (and perhaps why) a casting conforms or does not conform to engineering requirements. We have the equipment and expertise to fulfill this increasingly rare (but still important) need as well.

Failure Analysis

Failure Analysis is performed (usually in conjunction with dedicated engineering and failure analysis firms) to provide advanced dimensional measurement capabilities as well as expertise in support of metallurgical, chemical, physical, functional, or other testing used to determine the cause of failure and preclude its recurrence.

Force Testing

Q-PLUS Labs provides a variety of force testing services to all industries for countless applications. Tests can conform to ASTM, BS, DIN, ISO and other methods.

Force Testing Services include:

- Break

- Compression

- Creep

- Cyclic

- Deformation

- Extraction

- Fatigue

- Flexure

- Friction

- Indentation

- Insertion

- Peel

- Puncture

- Relaxation

- Rupture

- Shear

- Stress

- Tear

- Tension

Force Testing may be used for applications such as:

- Springs

- Syringes

- Plungers

- Needle insertion

- Adhesive strength

- Packaging quality

- Seals

- Textiles

- Tissue

3rd Party Independent Laboratory Dispute Resolution

Occasionally, disputes arise between sub-tier manufacturers and their customers, between prime contractors and their suppliers, or between exporters and importers. Right or wrong, good or bad, sufficient or deficient, conforming or discrepant, we’ll get to the truth of the matter. A biased inspector is not an inspector at all, but rather a “rejector” or an “acceptor.” Our inspections are performed by real inspectors: dedicated professionals who are in the information business and who work to the highest ethical standards. Anything less would simply invalidate what we do. This means our measurement data is impartial, unbiased, rational, factual, and based on valid and repeatable observations.

RECENT NEWS

Did you know? IIA’s Irvine, CA Lab has one of the Largest Area Laser Scanner CMMs in the U.S.