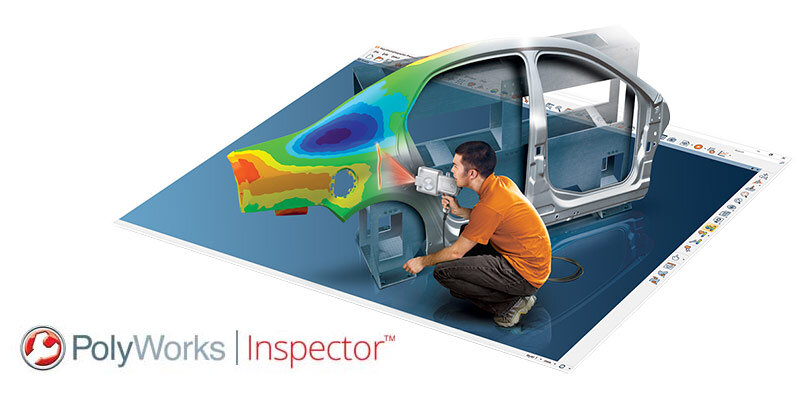

PolyWorks | Inspector

Defining the cutting edge of 3D metrology, the PolyWorks software suite maximizes productivity, quality, and profitability when integrating 3D measurement technologies into an industrial manufacturing process. From part and tool design and prototyping down to final inspection of assembled products, PolyWorks offers advanced solutions to cover the complete product development cycle.

ALIGN: Get the Alignment Right

ALIGN: Get the Alignment Right

Inspecting and analyzing a measured part is only possible if the digitized data is properly positioned and oriented in 3D. Typically, a measured part is aligned to its nominal CAD model to enable the extraction and comparison of nominal and measured dimensions. It can also be assembled virtually to the surrounding mating parts in order to check for interference issues or to analyze flush and gap deviations.

PolyWorks | Inspector offers a broad range of part alignment techniques that let users construct alignments with:

- Surfaces or cross-sections (measured-to-nominal best-fit, constrainable in rotation/translation, and within tolerance zone)

- Features (3-2-1, pairs of center points, and GD&T datum reference frames)

- Reference points and lines (RPS, surface points, and six-point nest)

- Virtual gauges (caliper, flush & gap, and airfoil)

MEASURE: Extract All Required Dimensions

At the core of the PolyWorks | Inspector workflow is the extraction of measured part dimensions and computing the deviations to their corresponding nominal dimensions. Thanks to the remarkable flexibility integrated into PolyWorks, dimensions can be extracted from measured point clouds, polygonal models built from point clouds, or probed points. Nominal dimensions can also be extracted from a CAD model or a reference measured part.

PolyWorks | Inspector delivers the complete toolbox you need to extract and analyze:

- Surface, boundary, and cross-sectional measured-to-nominal deviations

- Feature dimensions and GD&T controls (ASME Y14.5-2009 and ISO 1101, as well as PTB certified 64-bit/32-bit)

- Advanced dimensions such as flush and gap, profile radius, airfoil dimensions (leading edge, trailing edge, and global), assembly clearance, thickness, and more

PolyWorks | Inspector also offers real-time guidance to accurately build and inspect fixtures and jigs using single-point measurement devices.

REPORT: Generate Updateable Reports

REPORT: Generate Updateable Reports

PolyWorks | Inspector provides an outstanding updateable reporting technology that guarantees the exactness of a report and dramatically accelerates multiple piece inspection.

Report items, such as 3D scene screenshots and result tables, are automatically updated if a project is altered. You can modify the parameters of a project or replace the measured data points of the current piece by the data points from a new piece and know that the entire inspection report will automatically be updated.

Share Inspection Results

The PolyWorks | Viewer enables your colleagues, managers, and suppliers to review your inspection projects in 3D.

MULTIPLE PIECE INSPECTION: Simplify the Inspection of Multiple Pieces

Preparing an inspection project for a multiple piece inspection task has never been this easy. With DirectReplay, PolyWorks | Inspector literally does the work for you.

1. Create an inspection project and report for a first piece

2. Let DirectReplay automatically replay the same inspection on subsequent pieces

3. Focus on acquiring the 3D measurement data of the new pieces with your point cloud digitizer, single-

point measurement device, or both

Thanks to the relational inspection architecture of PolyWorks | Inspector, zero teaching is now a reality.

RECENT NEWS

Happy Holidays from your Friends at Q-PLUS Labs!

Q-PLUS Labs Welcomes Steve Mitchell as Master Scheduler

ALIGN: Get the Alignment Right

ALIGN: Get the Alignment Right

REPORT: Generate Updateable Reports

REPORT: Generate Updateable Reports