6 Rapidly Advancing Areas in Dimensional Metrology

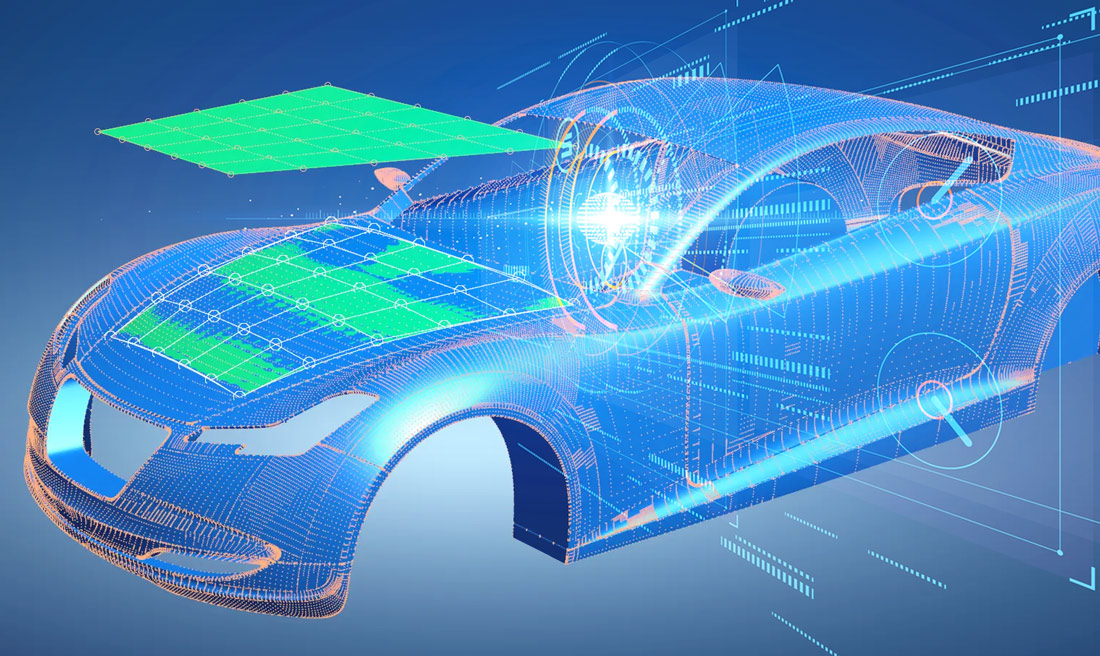

Dimensional metrology is a field that is constantly evolving, driven by the need for ever-increasing accuracy and precision in a wide range of measurement processes. In recent years, advancements in technology have led to a significant expansion in the range and scope of dimensional metrology techniques, allowing for more sophisticated measurement capabilities and greater ease of use. For example, the introduction of 3D scanning technology onto the shop floor has revolutionized dimensional metrology by enabling the capture of large amounts of detailed data about an object’s geometry in a matter of seconds in real-time during the production process.

Such advancements in the field of dimensional metrology have been fueled by the convergence of multiple technological domains, such as optics, sensors, robotics, and computing. The development of new measurement techniques, as well as the improvement of existing ones, has significantly expanded the capabilities of dimensional metrology. For instance, portable CMMs have evolved to become more user-friendly, accurate, and capable of conducting on-site measurements, while automation has helped to reduce errors and improve efficiency in measurement processes. Here are 6 areas that have expanded greatly and are continuously advancing in dimensional metrology:

Optical Metrology – Advances in optical metrology techniques, such as digital holography and confocal microscopy, have enabled the precise measurement of microscopic features and surfaces. These techniques use advanced optics and sensors to capture high-resolution images and data, allowing for accurate and detailed analysis of materials and components. Optical metrology is particularly useful in the medical industry, where the measurement of features on the micro-scale is essential.

Portable CMMs – Portable coordinate measuring machines (CMMs) have become more accurate and user-friendly in recent years, making them ideal for on-site measurement applications. With the help of wireless connectivity and automated data analysis, portable CMMs can provide fast and accurate measurements in real-time. This technology is particularly useful in industries such as aerospace and shipbuilding, where large components must be measured in the field.

3D Scanning – With the help of laser or structured light, 3D scanners can capture millions of data points in seconds, creating a detailed digital model of an object’s geometry. The use of 3D scanning has become increasingly popular in dimensional metrology, as it enables the accurate measurement of complex shapes and surfaces. This technology is particularly useful in industries such as aerospace and automotive, where precise measurement of components is critical for safety and performance.

Automation – Automation has revolutionized dimensional metrology by reducing the risk of errors and improving efficiency. With the help of robots and other automated systems, dimensional metrology can be conducted with minimal human intervention, allowing for faster and more accurate measurements. Automation is particularly useful in industries such as automotive and other high volume applications, where complex components require a large number of measurements.

Metrology Software – Advances in metrology software have made it easier to capture and analyze measurement data, with features such as automated data analysis and visualization. This software can help streamline measurement workflows, reducing the time and effort required to conduct dimensional metrology. Metrology software is particularly useful in industries such as medical device manufacturing, where precise measurement and documentation of components are critical for regulatory compliance.

Non-Contact Measurement – Non-contact measurement techniques, such as white light interferometry and laser profilometry, have become more accurate and efficient in recent years. These techniques allow for the measurement of delicate or hard-to-reach surfaces without the risk of damage or distortion. Non-contact measurement is particularly useful in industries such as optics and electronics, where delicate components must be measured without contact.

Overall, the latest advancements in dimensional metrology are providing engineers with powerful tools for accurate and efficient measurement of manufactured parts. These advancements are improving the quality and reliability of products across a wide range of industries and are expected to continue driving the evolution of the field in the coming years.

How Q-PLUS Can Help

At Q-PLUS Labs, we specialize in providing high-quality dimensional metrology services to a wide range of industries. Our team of experienced technicians uses state-of-the-art equipment and techniques to provide accurate and reliable measurements for your applications. We use and deploy all the aforementioned technologies and make them available to you when you need them. Contact us today to learn more about our services and how we can assist you with your dimensional measurement & inspection needs.

Leave A Comment

You must be logged in to post a comment.